Automotive Engines

Automotive Engines, Diagnosis, Repair, and Rebuilding Eighth Edition

This comprehensive resource provides detailed content on the theory of operation, diagnosis, repair, and rebuilding of automotive engines. Learners will gain essential technical expertise as they develop the skills and knowledge they need for professional success, including critical thinking and awareness of key industry trends and practices. AUTOMOTIVE ENGINES: DIAGNOSIS, REPAIR, AND REBUILDING, Eighth Edition, emphasizes universal repair techniques and case histories based on real-world scenarios to prepare users for careers in the field. Instructor resources include lesson plans, customizable lab sheets that address ASE Education Foundation Standards, a customizable test bank with questions based on chapter content, PowerPoint® presentations, and more. Now updated with new, full-color images and information on the latest trends, tools, and technology—including hybrid engines and high-performance components—this trusted resource is the ideal choice for automotive instructors who want a complete teaching package for their Engines course.

-

You must be an instructor to receive a desk copy. Please include your name and the name of your school in your request.

What’s new in the 8th Edition?

This eighth edition of Automotive Engines has been updated and refined to reflect changes in the marketplace. The seventh edition was produced in a four color design for the first time with many new and updated photos and illustrations. This has been a tremendous improvement. An emphasis on photos and art anticipates the needs of those with different learning styles and encourages student interest in reading the related text. New color photos and illustrations have been added to this eighth edition to continue improving this project. The design and engineering of the internal combustion engine is continuing to evolve, with enhancement of high-performance sport compact cars and vehicle restoration accounting for a substantial part of the industry.

Here is a listing of some of the highlights:

- The updated high-performance Section 5 includes three chapters with updated information on engine breathing, including intake and exhaust manifolds, turbocharging, supercharging, high-performance camshafts, and variable valve timing.

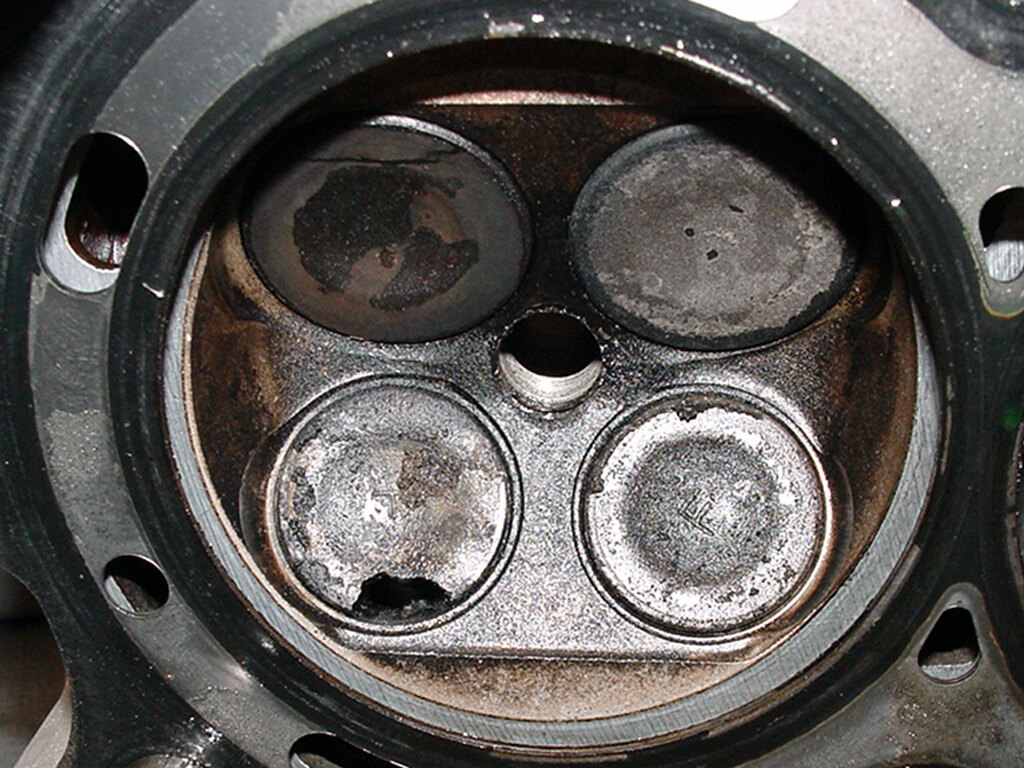

- Up-to-date information on cooling and lubrication systems is included in this edition of the text. Engines last far longer than they did 25 years ago. Maintenance is important to vehicle owners; cooling system failures that result in serious engine damage must be avoided.

- Metric micrometer reading has been expanded in Chapter 6. New or updated case histories highlight real world situations, providing more critical thinking practices.

- Vintage Engines additions help put newer technologies in historical perspective by offering interesting facts about older technologies while separating them from the core text, along with accompanying photographs.